mechanical engineering, metalworking, turning for medium to large finished products, laser cutting

ME.CA.T.

High technology for customer service

ME.CA.T. was founded in 1972 on the initiative of three partners who, on the strength of their work experience, set up a business focused on piping for petrochemical plants. Since then the company has expanded and metalworking has been joined by mechanical processing.

Since 1996, it has been owned by the Di Giorgio family who administer it in the persons of Mario, Luca and Paolo.

Since 2000, the acquisition of turning machinery with working lengths up to 10 metres has allowed the offer to be expanded and new production sectors to be entered.

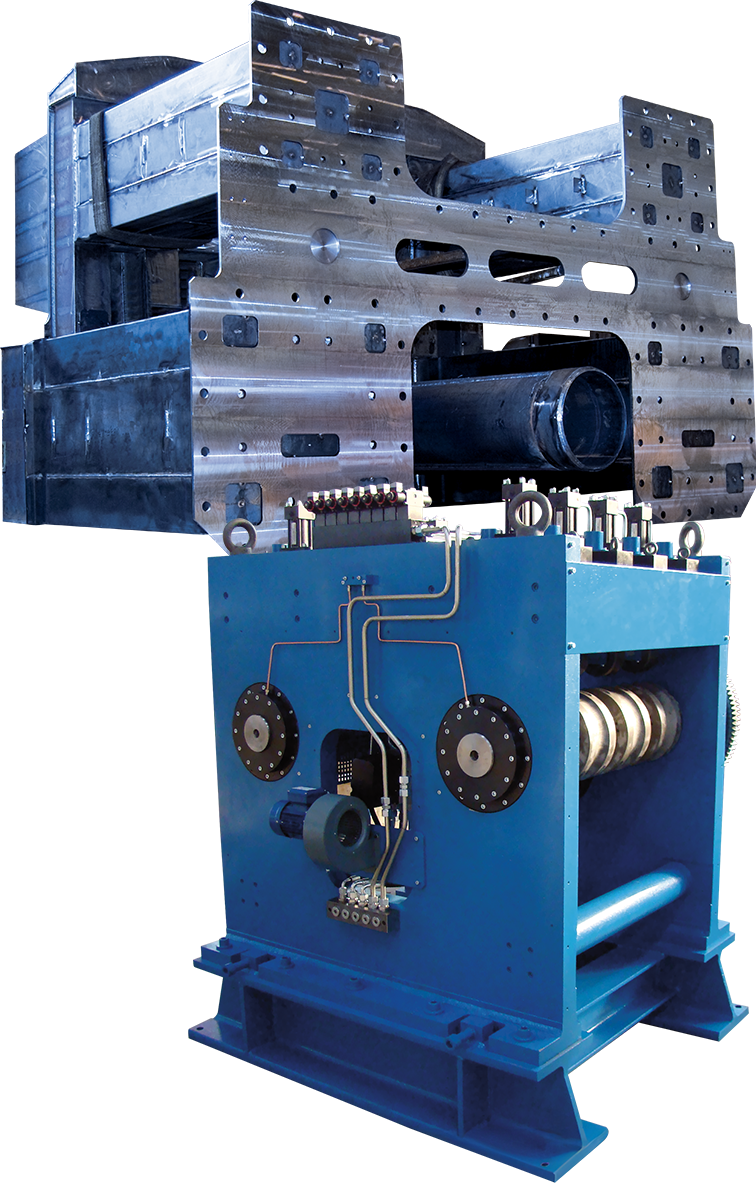

ME.CA.T. operates principally in the sector relating to the construction of machinery for the processing of plastics and in the steel, paper and printing machinery sectors, dedicating itself almost exclusively to medium-large finished products.

It is also able to provide quality services in the steel and packaging machinery sectors.

The vast experience gained in over fifty years of activity and constant technological evolution have allowed the company to position itself on the market as a supplier specialising in made-to-order products.

Strengths

The strong points of the ME.CA.T. plant are the perfect synergy between the large dimensions and the production potential of the machinery, and the particularly versatile organisation chart.

Continuous attention is paid to in-house training with the consequent enhancement of human resources.

Inside the plant, the organisation is divided into five main departments: boring, milling, turning, sheet metal, assembly.

The production chain is completely computerised and an advanced production data collection system contributes significantly to the optimisation of the production cycle.

This guarantees the best monitoring of activities and effective management of emergencies.

Order management

In ME.CA.T. work planning is a weekly matter.

The production management programme makes it possible to check work advancement and order completion in real time.

At the business end of the process it is possible to verify all the information relating to the order, including personnel management and hours/operator reporting.

This system of organisation of the production unit translates into better service for our customers.

Customer service

Technological innovation and organisational capacity make ME.CA.T. and the companies in the Group, a sure point of reference for the entire mechanical processing sector.

The ability to adapt to the needs of the market and customers means we can provide a focused consultancy service and production on demand.